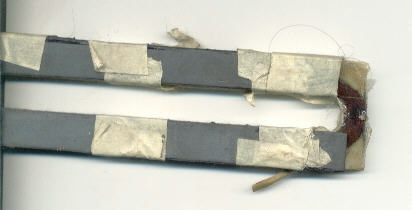

The First Working Set was the prototype coils, bedded in epoxy so I could handle them to experiment with different magnet configurations.

For comparison, the sound of the old standard arrangement of piezo and microphones was used on the last CD, "A Hobo's Dulcimer", and the sound of my old acoustic hammered dulcimer with just microphones is on older CDs. Tracks and clips from these are available on the Music Page:

Pickup set 1: 6500K winds

18" (righthand)

with ceramic bar magnets attached to the sides of the coil:

18" (lefthand)

with full-width ribbon magnet and steel plate beneath the coil, coil placed beneath the string:

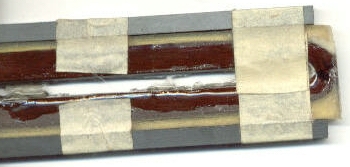

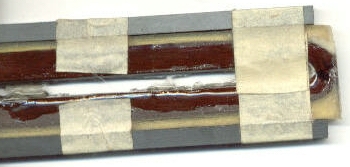

with ceramic bar magnets attached to the sides of the coil and steel plate beneath the coil (pictured):

placed beneath the strings:

placed above the strings:

When the pickup was below the strings, it was closer to the to the strings already sensed by the other coil than the strings that needed to be picked up. The result was that the pickup had to be placed above the strings, even though there it will get in the way of reaching the far left treble bridge. Though since it rides in the "low" area where the strings cross, it is more a matter of learning to avoid the pickup when I am playing now that it is there, eventually that will be automatic. There's also a problem with it bridging such a large gap suspended above the strings, with the magnets trying to suck it down to the strings, bending the coil out of true. I placed a support in the middle, and will try backing the pickup away from the strings, or try weaker magnets. Of course, both of these decrease response. All the nature of experimentation. The solid aluminum bobbins of the next set will support the coil better than just potting the coil in epoxy, which is still pretty soft and flexible.

Pickup Type 2

18" Bridge (designed to fit around the center bridge and sense on both sides of the bridge)

This single pickup was able to sense all the strings, but the strings on the top, on either side of the bridge, were only sensed once, on each side of the coil, while the strings passing through the bridge and under the coil were sensed by both sides of the coil and were twice as loud. I tried to bias the sound by placing the magnets on top, and trying to get closer to the upper strings, but with my present bridges the gap between the strings is quite narrow, so I couldn't get far enough from the lower strings to make a difference. It still might work with a different, higher center bridge, so the pickup can be biased closer to the upper strings.

with a ribbon magnet on top of each side the coil:

mixed with the right pickup, side by side comparison, punch in/out mix sequence: center, center+right, right, center+right, center:

sorry, haven't had time to clip and mix this sound sample for you, though since it didn't work, its not so important

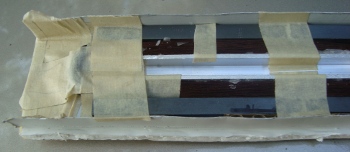

Pickup set 2: 5500K winds

Looking at the results from the step test, I reduced the winds to 5500K. Also, I incorporated permanent aluminum bobbins into these pickups for a stiffer integral support, because the epoxy is slightly flexible, and the strength of the magnets is causing the center of these long coils to bend closer to the strings in the center, increasing their volume compared to the strings at the top and bottom.

The coils came out looser than I want, either because I am not putting enough tension on the wire for fear of breaking it, since I have no easy way to guage how much tension I am putting on it, so need a guage of some sort so I can tighten it to the breaking point, back off a little, and set it to that point consistently. Or I need to change the alignment of the bobbin to the wire guide to that the tension is distributed better to the coil, maintaining a constant tension. I think I might have to lower the bobbin below the level of the wire guide so there is not a momentary slack point as the bobbin rotates to the in-line position.

I tried three methods of potting and generally finishing these coils.

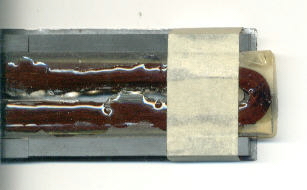

The first 18" coil I wound just on the aluminum bobbin, then used posterboard to cover the sides of the coil before immersing it in wax.

For the second 18" pickup in the set, I placed aluminum sheeting on both sides with foam stiffeners, then wound the coil. Unfortunately, it was too big for the trough I melt the wax in. I took off one side, carefully capturing the loose wire and taping it down, then bent up the sides of the remaining sheet aluminum to form the top of a case, and decided to place the magnets in the case with the coil before potting it in the wax, to make sure the magnets would fit in place exactly to the coil, easy to do before potting.

The 8" coil I made by placing a sheet aluminum piece on one side and a piece of aluminum-foil wrapped posterboard on the other side, adding a piece of foamboard to each side to stiffen them, then winding the coil. I placed the entire piece in the liquid wax to soak, then pealed off the foam board.